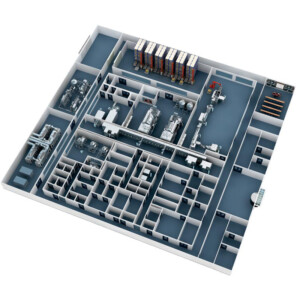

Have limited funds to start up your own production line? Don’t worry, we have you backed up!

Check out our starting up package for small scaled peptide production line package.

1.Preparation Stage:

Equipment: Vial washing machine, oven (referred to as ‘Baker’ for drying), clean vials.

Process: Thoroughly clean, wash, and dry all vials and equipment to eliminate contaminants and ensure a sterile environment for peptide production.

2.Solution Preparation:

Equipment: Blender for mixing, raw peptide materials, ultrasound machine for dissolution, super clean table for a contaminant-free workspace.

Process: Mix purified water with peptide ingredients in a sterile blender, stirring until dissolved. Use an ultrasound machine to ensure complete dissolution without exceeding 30°C to maintain the integrity of the peptides.

3.Filtration:

Equipment: Micron filter (0.22 µm).

Process: Filter the solution to remove particulate matter, ensuring a pure and clear peptide solution ready for the next steps.

4.Aliquoting:

Equipment: Pipette gun, sterile small bottles.

Process: Use a pipette gun to accurately divide the solution into smaller, pre-sterilized bottles for individual doses, maintaining precision and sterility.

5.Plugging:

Process: Manually or automatically insert plugs into each bottle to seal the peptide solution temporarily before freeze-drying, preventing contamination.

6.Lyophilization (Freeze-Drying):

Equipment: Freeze dryer (lyophilizer), freezer for pre-freezing.

Process: Freeze the plugged bottles to solidify the peptide solution, then lyophilize under vacuum to remove water, preserving the peptides in a stable, dry state. After drying, the plugs are pressed firmly to seal the powder.

7.Capping:

Process: Securely cap each bottle to ensure the peptides are completely sealed and protected from environmental factors, ready for storage or shipment.