In the dynamic and rapidly advancing realm of biotechnology, the demand for peptides has been on an astonishing upward trajectory. Peptides, which are essentially short chains of amino acids, play a pivotal role in a wide array of applications. In the pharmaceutical industry, they are the building blocks for developing innovative drugs that can target specific biological pathways, offering potential cures and treatments for various diseases. In the cosmetics sector, peptides are utilized for their anti – aging and skin – rejuvenating properties, making them a sought – after ingredient in high – end skincare products. Moreover, in the research field, peptides are indispensable tools for scientists to study protein functions and cellular processes.

As the demand for these versatile compounds continues to swell, the importance of having efficient peptide production line equipment cannot be overstated. For businesses that are eyeing an investment in this machinery, a comprehensive understanding of the wholesale price inquiry process is of utmost significance. This process is far more complex than a simple cost assessment. It requires a meticulous evaluation of multiple aspects.

First and foremost, the cost of the equipment is a major factor. However, it is not just about the upfront purchase price. Hidden costs such as installation, maintenance, and potential upgrades over time also need to be taken into account. A lower – priced equipment option might seem attractive initially, but if it incurs high maintenance costs or becomes obsolete quickly, it could end up being a more expensive choice in the long run.

Secondly, the quality of the peptide production line equipment is crucial. High – quality equipment is more likely to produce consistent and high – purity peptides. This is essential, especially in the pharmaceutical and research applications where even the slightest impurity can have significant consequences. Quality can be evaluated through factors such as the materials used in construction, the precision of the manufacturing process, and the reputation of the equipment manufacturer.

Efficiency is another key consideration. The ability of the equipment to produce a large quantity of peptides in a short period can greatly impact the profitability of a business. This includes factors like the speed of peptide synthesis, the time required for equipment setup and changeovers between different production runs, and the overall throughput of the production line.

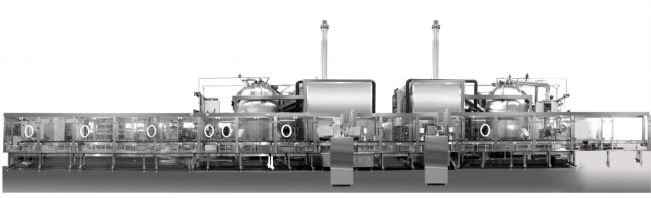

Technological advancements also play a huge role. Modern peptide production line equipment often comes with state – of – the – art features. For example, advanced automation capabilities are becoming increasingly common. Automated systems can handle tasks such as raw material feeding, reaction monitoring, and product collection with minimal human intervention. This not only reduces the risk of human error but also significantly cuts down on labor costs. Moreover, the integration of digital monitoring systems allows operators to keep a close eye on crucial production parameters in real – time. Parameters such as temperature, pressure, and reaction time can be precisely controlled, ensuring that the production process remains at optimal conditions throughout.

When considering peptide production line equipment, several other factors come into play as well. The scale of production is a primary determinant. If a company is engaged in small – scale peptide production, perhaps for research and development purposes in a laboratory setting, the equipment requirements will be different from those of a large – scale commercial manufacturer. Small – scale production might require more flexible and compact equipment that can handle a variety of peptide types in limited quantities. On the other hand, large – scale production demands high – capacity equipment that can operate continuously and efficiently to meet the demands of the market.

The type of peptides being synthesized also influences the choice of machinery. Different peptides have unique chemical structures and synthesis requirements. Some equipment is specifically engineered to handle particular types of peptide bonds. For instance, certain peptides with complex or sensitive bonds may require specialized equipment that can precisely control the reaction conditions to ensure high – yield and high – quality production.

In conclusion, the wholesale price inquiry for peptide production line equipment is a multi – faceted process. It involves a careful balance between cost, quality, efficiency, and technological features. By thoroughly considering all these factors, businesses can make an informed decision when investing in peptide production line equipment, setting themselves up for success in the highly competitive biotechnology market.

PeptideGurus is a leading supplier of American-made research peptides, offering top-quality products at competitive prices. With a focus on excellence and customer service, they ensure a secure and convenient ordering process with global shipping.

CONTACT