The demand for peptide production equipment in stock immediately has surged in recent years, driven by the rapid advancements in biotechnology and pharmaceutical industries. Peptides, short chains of amino acids, are essential in various therapeutic and diagnostic applications. As a result, having access to high-quality peptide production equipment is crucial for researchers and manufacturers aiming to streamline their processes and ensure timely delivery of peptide-based products. This article delves into the intricacies of peptide production equipment, highlighting the importance of having them readily available in stock.

Peptide synthesis is a complex process that requires precision and accuracy. The equipment used in peptide production plays a vital role in ensuring the quality and consistency of the final product. Automated peptide synthesizers, for instance, have revolutionized the field by allowing for the efficient and reliable production of peptides. These machines automate the repetitive and labor-intensive steps involved in peptide synthesis, significantly reducing the time and effort required. Having peptide production equipment in stock immediately can greatly enhance a laboratory’s or company’s ability to meet tight deadlines and adapt to changing demands.

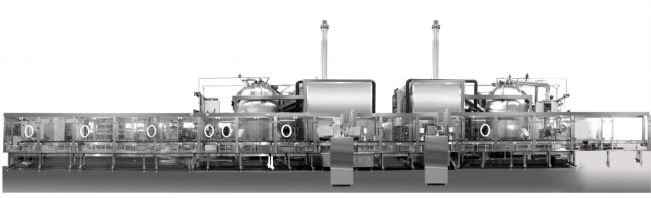

In addition to automated synthesizers, other essential peptide production equipment includes purification systems, analytical tools, and lyophilizers. Purification systems are crucial for isolating the desired peptide from a complex mixture of reaction by-products and impurities. High-performance liquid chromatography (HPLC) is commonly used for this purpose, providing high-resolution separation and analysis. Analytical tools, such as mass spectrometers and spectrophotometers, are indispensable for characterizing the synthesized peptides and ensuring their purity and identity. Lyophilizers, on the other hand, are used to dry and stabilize peptides for storage and transport. Ensuring that these equipment are in stock and readily available can significantly boost a facility’s productivity and efficiency.

The availability of peptide production equipment in stock immediately is not only important for large-scale manufacturers but also for small research laboratories and academic institutions. These entities often operate on limited budgets and cannot afford the downtime associated with waiting for equipment delivery. By having access to peptide production equipment in stock, they can maintain continuous workflow and focus on their research objectives without unnecessary interruptions. Moreover, the availability of equipment in stock can also facilitate collaborations between different research groups, enabling them to share resources and expertise.

One of the key challenges in maintaining peptide production equipment in stock is the rapid pace of technological advancements. As new and improved equipment is developed, older models may become obsolete or less efficient. Therefore, it is essential for suppliers and manufacturers to keep abreast of the latest innovations and update their inventory accordingly. This ensures that customers have access to the most advanced and efficient peptide production equipment available. Additionally, suppliers should provide comprehensive support and maintenance services to ensure the longevity and optimal performance of the equipment.

Investing in peptide production equipment in stock immediately can also have significant economic benefits. By reducing the lead time for equipment acquisition, companies can accelerate their production timelines and bring their products to market faster. This can result in increased revenue and competitive advantage in the biotechnology and pharmaceutical sectors. Furthermore, having equipment readily available can help companies respond quickly to market demands and capitalize on emerging opportunities. This agility is particularly important in the fast-paced and ever-evolving field of peptide research and development.

The importance of peptide production equipment in stock immediately is further underscored by the growing demand for personalized medicine and targeted therapies. Peptides are increasingly being used as therapeutic agents due to their high specificity and low toxicity. As the demand for these innovative treatments continues to rise, so does the need for efficient and reliable peptide production equipment. By ensuring that equipment is in stock and readily available, companies can better support the development and commercialization of peptide-based therapies, ultimately benefiting patients and healthcare providers.

In conclusion, the availability of peptide production equipment in stock immediately is a critical factor in the success of peptide research and manufacturing endeavors. It enables researchers and manufacturers to maintain efficient workflows, meet market demands, and drive innovation in the field of biotechnology and pharmaceuticals. As the industry continues to evolve, it is imperative for suppliers and manufacturers to prioritize the availability of high-quality peptide production equipment and provide exceptional support and service to their customers.

The role of peptide production equipment in stock immediately is not limited to the synthesis of therapeutic peptides. It also extends to the production of peptides for diagnostic applications, such as biomarkers and imaging agents. These peptides play a crucial role in the early detection and monitoring of diseases, providing valuable insights into disease progression and treatment efficacy. By ensuring the availability of peptide production equipment, researchers and healthcare professionals can advance the development of these diagnostic tools and improve patient outcomes.

Moreover, peptide production equipment in stock immediately is essential for supporting the growing field of peptide-based vaccines. Peptide vaccines offer several advantages over traditional vaccines, including improved safety profiles and the ability to target specific antigens. The COVID-19 pandemic has highlighted the importance of rapid vaccine development and deployment, underscoring the need for efficient peptide production equipment. By having these tools readily available, manufacturers can accelerate the development and distribution of peptide-based vaccines, contributing to global public health efforts.

PeptideGurus is a leading supplier of American-made research peptides, offering top-quality products at competitive prices. With a focus on excellence and customer service, they ensure a secure and convenient ordering process with global shipping.

CONTACT